PT. Lontar Papyrus Pulp and Paper

PT. Lontar Papyrus Pulp & Paper Industry (PT LPPPI) is located in Jambi Province, Southern Sumatra, about 100 kilometers from the Malacca Strait, which divides Sumatra Island (Indonesia) and Singapore. Precisely in Tebing Tinggi Village, Kec. High Cliff, Kab. Tanjung Barat, is +/- 135 km from Jambi City as the Capital of Jambi Province.

PT. LPPPI was established after Sinar Mas acquired PT. Wirakarya Sakti, in the 1990s, was one of several companies engaged in the pulp, tissue, and chemical production business of Asia Pulp & Paper (APP). In 1994 the company started pulp production with a capacity of 450,000 tons per year.

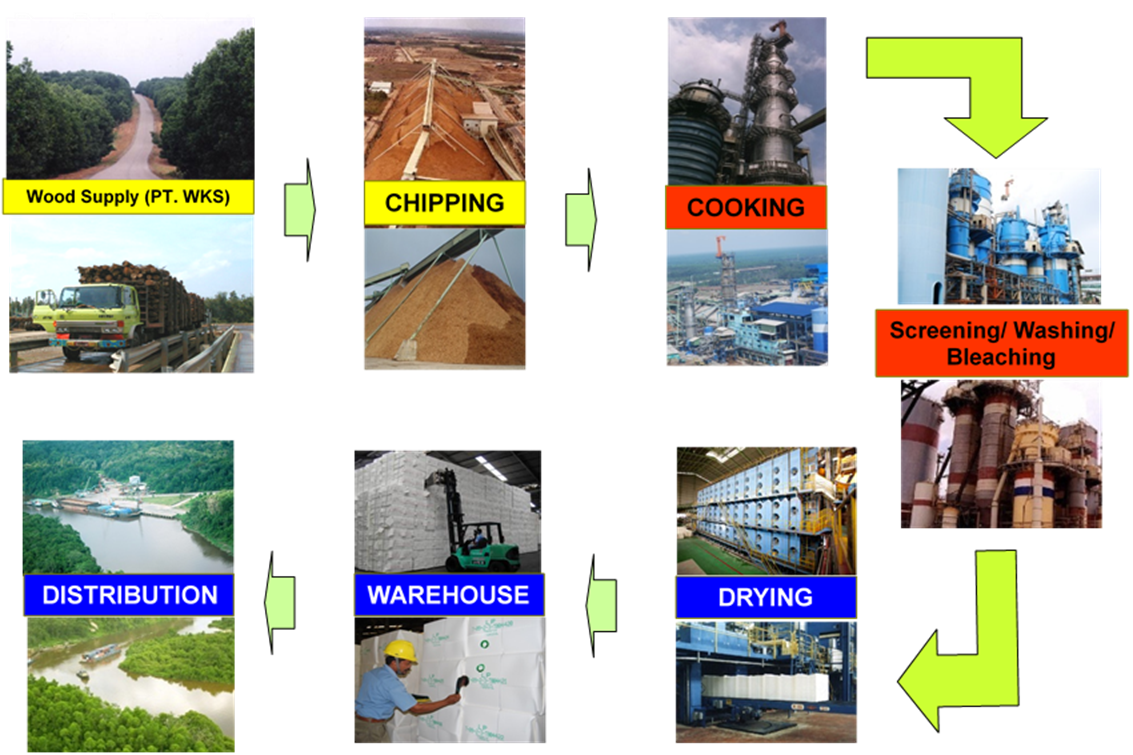

Raw materials PT. Lontar Papyrus Pulp and Paper Industries originates from Industrial Plantation Forests managed by PT. Wirakarya Sakti on an ongoing basis. All its wood suppliers have a Timber Legality Verification System or SVLK certificate.

The proximity to the PT Wirakaryasakti Industrial Plantation Forest concession area makes the product development process more manageable. With the existence of a Research and Development development site, various innovations to make the production process more sustainable can also be produced. Increasing the ability to grow plants, discovering new varieties that are superior and useful, and increasing the amount of seed production for industrial plantation forest areas can shorten the time from planting to harvest so that the production process becomes more sustainable.

APP Sinar Mas through PT. Lontar Papyrus Pulp & Paper Industry has the vision to become the best and largest pulp and tissue producer in the world to meet the growing demand for paper, tissue, and world packaging products, with the spirit of continuous improvement and development by implementing the Management By Olympic System ( MBOS).

APP Sinar Mas through PT. Lontar Papyrus Pulp & Paper Industry has the vision to become the best and largest pulp and tissue producer in the world to meet the growing demand for paper, tissue, and world packaging products, with the spirit of continuous improvement and development by implementing the Management By Olympic System ( MBOS).

ISO

PEFC Chain of Custody Certified

Valid From

18 Jan 2023

Valid From

18 Jan 2023

Certificate ISO 14001:2015 SGS UKAS 2018-2021

Starting from:

27 Agustus 2018

Starting from:

27 Agustus 2018

Certificate ISO 9001:2015 SGS UKAS 2019-2022

Starting from

24 October 2019

Starting from

24 October 2019

Sertifikat ISO 50001 2018 2021-2023

Starting From:

20 Januari 2021

Starting From:

20 Januari 2021

Health & Safety

OHSAS 18001:2007

Starting from:

30 April 2018

Starting from:

30 April 2018

Product Specification

Sistem Manajemen Keselamatan dan Kesehatan Kerja

From

14 Juni 2017

From

14 Juni 2017

Chain of Custody

HALAL CERTIFICATE

Valid until

16 Mei 2018

Valid until

16 Mei 2018

Halal Assurance System Certificate

Starting From:

16 Mei 2018

Starting From:

16 Mei 2018

Awards

.jpg/825b52eb-13c1-bdc9-e764-7e8f805326bf)

SLGS_Green Label Certificate_ TJIWI KIMIA

Starting From:

16 Mei 2019

Starting From:

16 Mei 2019

SVLK

TÜV Rheinland SVLK Certification

Starting From :

17 Agustus 2015

Starting From :

17 Agustus 2015

The main product of PT. Lontar Papyrus is pulp (pulp), and the current installed capacity has reached 3,100 AD Tons per day or 1,100,000 AD Tons per year using the Sulfate (Kraft) cooking method. The cooking tank (Digester) uses a continuous system to cook large quantities of raw flakes in the form of acacia mangium, acacia crassicarpa, and eucalyptus spp. LBKP pulp is produced by using supporting chemicals that are free of elemental chlorine (Elemental Chlorine Free).

In 2020 production will reach more than 1 million tons, most of which is used for the domestic industry. Around 140 thousand tons are exported annually to various countries such as China, India, Vietnam, Australia, and the United Arab Emirates.

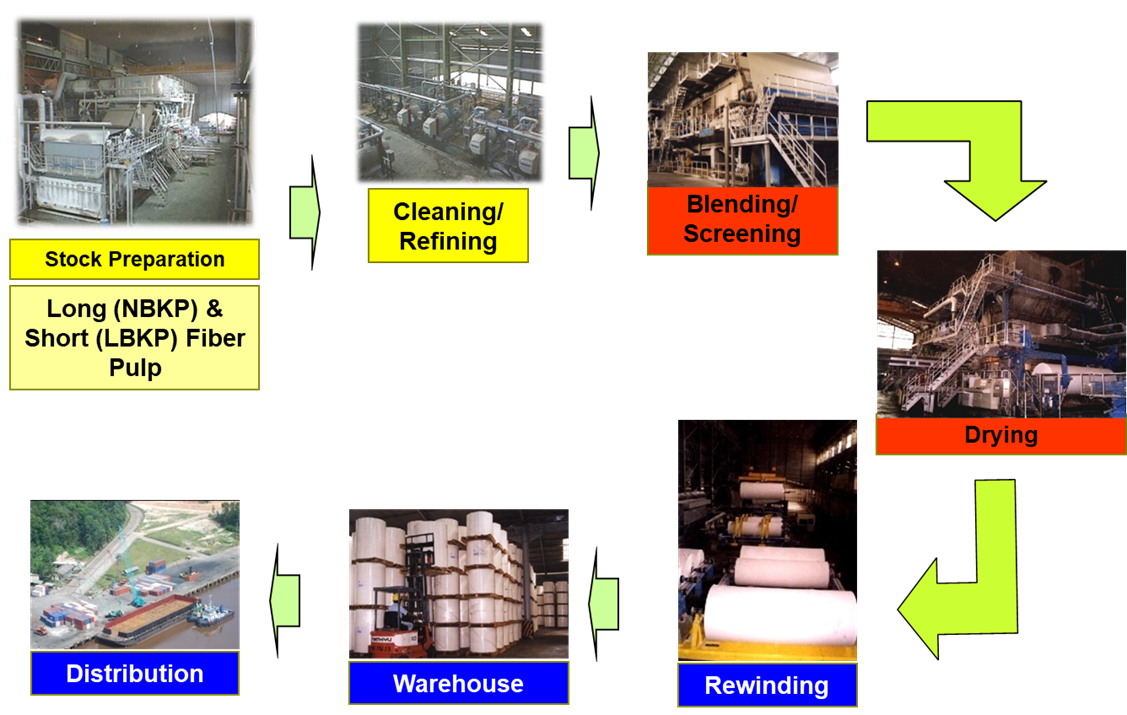

Besides pulp since March 1998 PT. LPPPI has started up the first jumbo roll tissue paper factory (TM# 1) with product types such as facial, toilet, napkin, and kitchen towel tissue paper. Commercial production since May 1998. The product produced is a Tissue Jumbo Roll with an installed capacity of 60,000 tons per year. Currently PT. LPPPI already has eight units of Tissue Machines with an installed capacity of 254,000 tons per year. This capacity will be continuously increased in stages until it reaches 1,000,000 tons per year, with the majority of export markets in 55 countries, including America, England, and Australia.

Besides producing Pulp and Tissue PT. LPPPI also produces certain chemicals as internal process support materials, such as NaOH, HCl, Ar, O2, SO2, H2SO4, and ClO2.