Sustainability

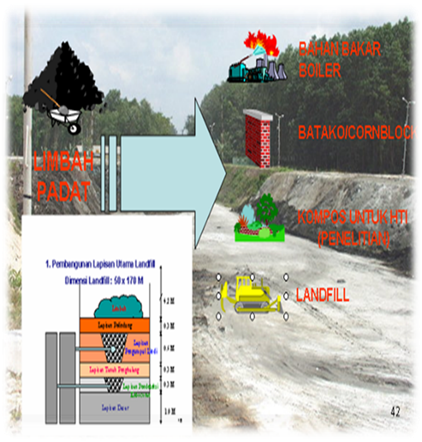

This factory utilizes its solid waste to be processed into fertilizer for its industrial plantation forests, the rest is processed in a particular processing site. Likewise, with liquid waste. All are regulated according to government regulations to meet ISO 14001 certification standards.

SERTIFIKASI DAN PENGHARGAAN

For customer satisfaction with product quality, from the beginning of factory operations, a Quality Management System was adopted by awarding the ISO 9002 certificate on October 24, 1995, on the results of an audit conducted by the SGS Yarsley Certification Body from England. Also, for concern for the environment PT. LPPPI received a certificate for the first time in the environmental quality management system ISO 14001 on August 19, 1997, also by SGS Yarsley. Currently PT. LPPPI already has almost all management system certificates which are continuously updated to meet market needs. These certificates are ISO 9001: 2008 (QMS-quality management), ISO 14001:2004 (EMS-environmental management), ISO 18001:2015 (OHSAS-Occupational Health and Safety Management), ISO 50001:2011 (EnMS – energy conservation), and Halal Guarantee from BPOM MUI. Certification in the field of supply of wood raw materials by testing the supply chain of wood from the beginning to the final product has also obtained certificates in the form of SVLK, CoC-PEFC, and CoC-LEI certificates.

For business continuity, the industrial area of PT. The LPPPI has been designated as the Industrial Sector National Vital Object (OBVIT Nas) by the Minister of Industry through the National Police Chief since 2014. PT. LPPPI has also received the PROPER award from the Ministry of Environment and Forestry and the Green Industry Award from the Ministry of Industry

Responsibility and Sustainability In All Operations

Environmental Protection The Company operates in compliance with the national laws and regulations on fibre procurement, environmental protection, and occupational health and safety. The laws and regulations are embedded into the Company’s policies and operating procedures which are continuously monitored. The Company has received ISO 14001 certificate for Environment Management System (EMS). The Company first received the certificate in 1997. The conversion to 2015 version was carried out in 2016 and successfully obtained ISO 14001:2015. The certificate is valid until 2021.

The Company also has ISO 9001 certificate for Quality Management System (QMS). This certificate was first achieved in 1995. The Company has completed surveillance audit in 2016 while simultaneously converting the QMS to 2015 version and obtaining an 2015 version and The Company has successfully extended its validity until 2022.

The Company’s application of international standard provides assurance to the customers globally that the Company follows a process that is consistent with the most stringent standards in the industry.

The Ministry of Environment and Forestry of Republic Indonesia has established a multi-level assessment system based on the requirements of its government environmental evaluation programme (PROPER). Based on the 2019-2020 evaluation, the Company achieved “Blue” rating, which means the company has complied with all government regulations related to the environment. The Company practices good resource stewardship which is translated into policies to reduce waste such as the Source Control Policy and the “three Rs” (Reduce, Reuse, Recycle) Policy. To reduce pollutants, the mills’ wastewater treatment plants utilise activated sludge as well as physical and chemical treatments to ensure that the effluent discharged into the river meet government standards.

The Company is committed to uphold the highest standards in health and safety management of its workers and the working environment as required by the national laws and regulations. As mandated by the Ministry of Manpower and Transmigration’s Decree, the Company has implemented SMK3 (Occupational Health and Safety Management System) in all the Company’s mills and has received the SMK3 certification. The SMK3 certificate first achieved by the Company in 1998 and has been renewed in 2018.This certificate is valid until 2020.

The Company has also applied ISO 45001, an internationally recognised standard for occupational health and safety. In 2020, the Company has successfully completed ISO 45001 migration audit. This certificate is valid until 2023.

High Quality Products

The Company is fully committed to produce high quality tissue products. Its products are marketed in both domestic and international markets. The mills’ products comply with product safety regulations including standards set by USA, European, Japan, and other Asian markets. The tissue products that are produced by the Company have obtained Halal certificates from MUI (Indonesian Ulema Council) since 2008. Recertification audit was conducted in 2018 and this certificate is valid until 2020.

The Company has also successfully obtained a Halal Guarantee System certificate since 2011. Recertification audit was conducted on 2020 and this certificate is valid until 2024.

Aspects of Products Responsibility, Customer Health and Safety Regarding the health and safety of customers when using our products, the Company provides MSDS (material safety data sheet) for various pulp and tissue products.

Responsible Supply Chain System

All pulp used by the Company have chain of custody documentation to ensure traceability back to the original sources. This Chain of Custody system aims to ensure that no illegal or controversial source fibre enters the supply chain. Implementation of the system is verified by an independent certification body, through audits under the scheme of PEFC, SVLK and others. The Company has achieved the CoC certificate from PEFC (Programme for the Endorsement of Forest Certification) in 2008. PEFC is a leading, internationally recognised forest certification endorsement programme promoting responsibly managed forests. With 55 national members, 48 endorsed national certification systems and about 320 million hectares of certified forests; PEFC is the world’s largest forest certification system. This certification signifies that the fibre that the mill uses for their production coming from sustainably-managed forests. The Company’s current PEFC-CoC certificate is valid until 2024.

Relevant to the Government of Indonesia’s laws and regulations, the Company is committed to operate according to the Sistem Verifikasi Legalitas Kayu (SVLK)1 or Timber Legality Verification System. SVLK is a system devised by the government of Indonesia, in collaboration with national and international stakeholders, to ensure that all Indonesian timber products traded and distributed have clear legal status and clear traceability. Countries that import Indonesian timber products have the assurance that products certified with SVLK have complied with strict standards for timber legality, which can be seen as compatible and equal to Chain of Custody (CoC) systems set by other countries.

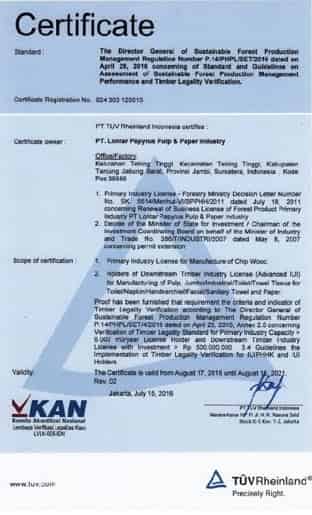

Since November 2016, the European Union has formally acknowledged the SVLK as a standard recognised in the framework of Forest Law Enforcement, Governance and Trade (FLEGT) through the activation of FLEGT-VPA (Voluntary Partnership Agreement) between the European Union and Indonesia. By the activation of FLEGT-VPA, products with SVLK logo would be able to enter the EU market without undergoing due diligence process. The Company’s mills first achieved SVLK certification in the end of 2012. The certification audit was conducted by PT TUV Rheinland Indonesia, an independent certification service company that is a member of TUV Rheinland Group headquartered in Germany. The certificates valid until 2021.

APP Group Sustainability

Growing Our Tomorrow

Our vision is to produce efficient and innovative pulp and paper through responsible forestry practices.

Learn MoreCSR

1. Community Services (Charity)

PT Lontar Papyrus Pulp Paper Industries has brought many benefits to the surrounding community. Opinion of the people's economy increased rapidly, and the growth of employment both directly sympathized with the presence of this factory or indirectly, such as increased trade between regions to meet the needs of factory workers and their families.

2. Infrastructure

In addition to the economy, the level of health, education and community expertise in processing natural resources has also increased. With the presence of various facilities and infrastructure made by the factory community, access to improve life is even easier. The distance to the nearest city is much reduced.

- Pembangunan Klinik

- Pendidikan

3. Technology Integration

Through the integration of technology, resources, and innovative research and development capabilities, PT Lontar Papyrus Pulp and Paper Industri is committed to being at the forefront of the sustainable pulp and paper industry and having a positive impact on the surrounding community.

4. Flagship CSR Programmes

The Company believes that to carry out sustainable operation, the Company must have a positive impact on the environment and its surrounding communities. As a responsible company and embodiment of APP Sustainability Roadmap Vision 2020, the Company is committed to support the communities living inside and around the operational area. Guided by the UN Sustainable Development Goals, through CSR program implementation, the company focuses predominantly on community empowerment.

In 2020, several flagship CSR activities included empowerment of organic fertilizer groups, farmers empowerment in Teluk Nilau Village, company’s Community Development (CD) Center, empowerment of MSMEs producing snacks, and woven strapping groups. The Company also has routine programs including support for local health center and free health services. Regarding the COVID-19 pandemic, the company supports efforts to prevent and mitigate the pandemic by carrying out a Clean and Healthy Lifestyle (PHBS) campaign, wearing mask, washing hands and keeping distance (3M) campaign, provide masks and personal protective equipment (PPE) as well as foods.

In the agricultural sector, the company collaborates with Agriculture Service of the Tanjabar Regency. The Company provides land for community agriculture with collaboration mechanism between the community and the Company. The community are facilitated to carry out agricultural activities in the Company’s land area at the Community Development (CD) Center, Tebing Tinggi subdistrict and other locations in Suak Samin Village. The Company also facilitate soft loans, assisting, training and strengthening networks with the local agriculture agency. Five farmer groups join to this program with various crops such as watermelon, vegetables and oranges.

The empowerment program for cattle farmers continue in 2020. The Company collaborated with Farming Office of Tanjabar District, where, through an agreement with the Animal Husbandry Service, the Company supported the supply of 500 liters of liquid nitrogen per month, provided capacity building through training for farmers and other support. Meanwhile the Animal Husbandry Department would assist farmers related to cattle breeding techniques, hiring IB Officers (Inseminator), group organizing and cattle development. The program aims to improve farmers’ access to ownership of quality cattle resources, increase cattle birth rates and increase farmers’ income and welfare. This program contributed to bring Tanjabbar Regency as the largest cattle-producer in Jambi Province.

The Company supports community empowerment through development of organic fertilizers for agriculture. Fertilizers are then distributed to the forestry concessions of PT. Wira Karya Sakti (WKS). Support is given to the Sido Makmur composter group, Purwodadi Village. The Company provide capacity building through composter training, assistance, soft loan support and compost production infrastructure. The soft loan is used to support the production activities of the composter group by procuring trucks for transportation and building warehouses. With this additional supports, the production process of the composter group becomes more efficient and safer, with higher quality.

Women economic empowerment is also one of the Company strategic programs. The activities carried out include MSMEs focusing on woven handicrafts from plastic straps waste, as well as snacks such as crackers, sweet potato chips, and banana chips. The Company provides training, equipment and marketing networks. In 2020, the Company also facilitates MSMEs with online business training in collaboration with Blibli and tokopedia. This program aims to increase capacity building of online marketing, particularly during the COVID-19 pandemic.

5. Involvement in the United Nations Global Compact Initiatives

2019 was the Company’s twelfth year as a member of the United Nations Global Compact (UNGC). Through its involvement with the Global Compact, the Company has learned from the initiatives of its peers and shared some of its own successes that had helped strengthen its implementation of the Global Compact Ten Principles. The principles of the Global Compact provide a foundation for the Company to aim towards the goal of becoming a leading and respected global pulp and paper manufacturer and world class sustainability leader dedicated to providing superior value to all of our stakeholders. The Company is also actively involved in the Indonesia Global Compact Network (IGCN) which consists of companies in Indonesia that endorse the ten principles of the Global Compact.

6. UN Global Compact CEO Water Mandate and Indonesia Working Group

Since the Company pledged to the UN CEO Water Mandate in 2011, the Company has been focusing on responsible water management both inside the operations and outside. The Company through APP has also been leading the Indonesia Water Mandate Working Group for various water campaign activities involving multi stakeholders. Details of these activities are described in the APP Sustainability Report and the Indonesia Global Compact Annual Report.

As a company that committed to responsible water management, the Company has initiated water footprint assessments of all of its mills. In 2016-2017, the Company through APP led a multi stakeholder project in addressing water security and quality in small islands. APP, Habitat for Humanity Indonesia and Indonesia Institute of Sciences (LIPI), under the umbrella of IGCN, collaborated with UNESCO in initiating a project on the awareness-raising on water and waste management in the community in Pari Island, one of the islands in the north of Jakarta.

As the Chair of the Indonesia Water Mandate Working Group, the Company through APP has been leading various activities that aim to raise awareness of the importance of responsible water management. The activities include regular meetings to update and discuss local and international regulations on water, campaigns through various events, as well as the development of campaign materials including Indonesia Global Compact Water Action Report.